A modern supply chain is a complex ecosystem of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer. It encompasses everything from the sourcing of raw materials, production, and inventory management to logistics, warehousing, distribution, and customer delivery. In today's global economy, as highlighted by institutions like the Council of Supply Chain Management Professionals (CSCMP), an optimized supply chain is critical for:

- Competitive Advantage: Enabling faster delivery, lower costs, and better product availability.

- Customer Satisfaction: Meeting and exceeding customer expectations for speed, reliability, and transparency.

- Financial Performance: Directly impacting revenue, cost of goods sold (COGS), working capital, and profitability.

- Business Resilience: Ensuring continuity and adaptability in the face of disruptions.

Supply Chain Outsourcing (SCO) refers to the strategic delegation of some or all of an organization's supply chain activities to specialized third-party providers. This can range from outsourcing discrete tasks, such as freight transportation or warehousing, to engaging a partner for end-to-end supply chain management. The scope can include:

- Transactional Outsourcing: Specific, often repetitive tasks.

- Functional Outsourcing: Entire functions like logistics (Third-Party Logistics or 3PL) or procurement.

- Strategic Outsourcing: Comprehensive management and optimization of the entire supply chain, often involving Fourth-Party Logistics (4PL) providers or specialized Business Process Outsourcing (BPO) firms.

Historically, SCO was primarily driven by a desire to reduce direct costs associated with labor, assets (like warehouses or trucks), and basic operations. While cost efficiency remains a significant factor, the rationale for outsourcing has matured. As noted in publications like Supply Chain Management Review and reports by leading analysts such as Gartner's Supply Chain research, businesses now view SCO as a means to:

- Access specialized expertise and advanced technologies.

- Improve operational flexibility and scalability.

- Enhance focus on core competencies.

- Mitigate risks and build more resilient supply networks.

- Drive innovation and improve customer service. This shift reflects a move towards viewing outsourcing providers not just as vendors, but as strategic partners integral to achieving broader business objectives.

Several critical impact bearing factors are compelling US businesses, from SMBs to large enterprises, to increasingly consider supply chain outsourcing:

- Globalization and Complexity: Managing international sourcing, multi-modal transportation, and diverse regulatory environments demands specialized knowledge.

- Customer Expectations: The "Amazon effect" has conditioned customers to expect fast, free, or low-cost shipping and real-time visibility, pressuring businesses to optimize their logistics.

- Technological Advancements: The proliferation of Supply Chain Management (SCM) software, IoT, AI, and analytics offers immense optimization potential, but requires significant investment and expertise, which specialized providers often possess.

- Cost Pressures: Intense competition necessitates continuous efforts to reduce operational costs without sacrificing quality or service.

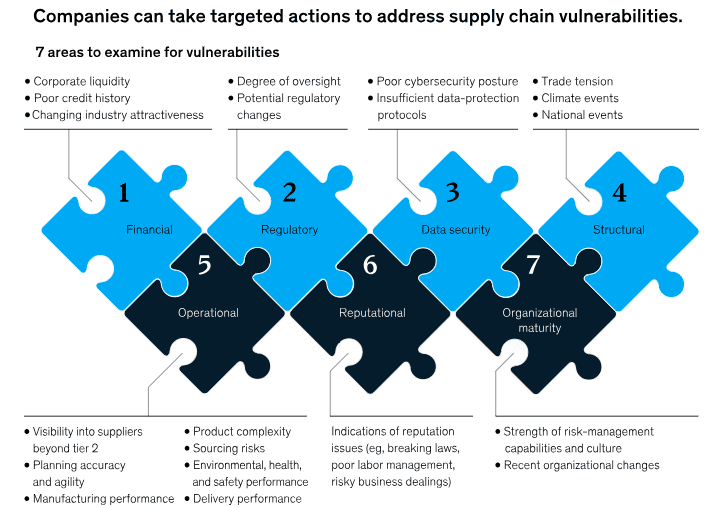

- Risk and Resilience Imperative: Recent global events (pandemics, geopolitical conflicts, trade wars, natural disasters) have highlighted the vulnerability of traditional supply chains, driving a search for partners who can enhance resilience and agility. [Refer to insights from organizations like the World Economic Forum on global risks].

- Focus on Core Business: Companies increasingly recognize the value of concentrating internal resources on product innovation, marketing, and customer relationship management, delegating non-core operational complexities.

The market for supply chain outsourcing, particularly for 3PL and 4PL services, has seen consistent growth and is projected to continue expanding. Market research firms like Armstrong & Associates (specializing in 3PL market research) or Mordor Intelligence regularly publish reports indicating a multi-billion dollar global market with strong year-over-year growth. This underscores the increasing reliance of businesses on external expertise to manage their supply chains effectively. The rise of e-commerce has been a particularly strong tailwind, fueling demand for sophisticated fulfillment and last-mile delivery solutions. For US business owners, this evolving landscape presents both immense opportunities to enhance their supply chain capabilities and significant complexities in choosing the right outsourcing strategy and partners. This guide aims to illuminate that path.

The scope of what can be outsourced within a supply chain is vast, catering to diverse business needs and strategic objectives. US businesses can delegate specific tasks, entire functions, or even end-to-end management. Understanding these common areas is the first step in identifying potential outsourcing opportunities.

Logistics and Transportation Management (The Arteries of Your Supply Chain)

This is one of the most frequently outsourced areas, focusing on the physical movement of goods.

- Freight Forwarding: Managing the international and domestic shipment of goods via air, sea, rail, or road.

- Fleet Management: Outsourcing the operation, maintenance, and optimization of a dedicated or shared transportation fleet.

- Last-Mile Delivery: Managing the final leg of delivery to the end customer, critical for e-commerce and direct-to-consumer (DTC) businesses.

- Transportation Spend Management: Optimizing routes, carrier selection, and freight auditing to reduce costs.

- Multi-Modal Transportation Coordination: Integrating different modes of transport for optimal efficiency and cost.

- Keywords: Outsource logistics, Transportation management outsourcing, Last-mile delivery services, Freight forwarding BPO.

Warehousing, Distribution, and Fulfillment (The Hubs of Activity)

Managing the storage and movement of goods within and out of facilities.

- Storage and Warehousing: Utilizing third-party facilities for short-term or long-term storage of raw materials, components, or finished goods.

- Order Fulfillment: Picking, packing, and shipping orders to customers (B2C or B2B). This is a cornerstone of e-commerce outsourcing.

- Cross-Docking Services:Unloading materials from an incoming semi-trailer truck or railroad car and loading these materials directly into outbound trucks, trailers, or rail cars, with little or no storage in between.

- Value-Added Services (VAS): Kitting, assembly, labeling, returns processing, quality checks within the warehouse.

- Inventory Placement and Network Optimization: Strategic positioning of inventory across multiple outsourced warehouses to minimize delivery times and costs.

- Keywords: Warehouse outsourcing, Order fulfillment services, 3PL warehousing, Distribution logistics outsourcing.

Procurement, Sourcing, and Supplier Management (The Foundation of Supply)

Strategic acquisition of goods and services needed for operations.

- Strategic Sourcing: Identifying, evaluating, and selecting suppliers globally.

- Supplier Relationship Management (SRM): Managing communication, performance, and contracts with suppliers.

- Procure-to-Pay (P2P) Process Outsourcing: Managing the entire lifecycle from purchase requisition to invoice payment.

- Spend Analysis: Analyzing procurement data to identify cost-saving opportunities.

- Contract Management: Overseeing supplier contracts and compliance.

- Indirect Procurement Outsourcing: Managing the purchase of non-core goods and services (e.g., office supplies, MRO items).

- Keywords: Procurement outsourcing, Strategic sourcing services, Supplier management BPO, Procure-to-pay outsourcing.

Inventory Management and Optimization (Balancing Demand and Supply)

Ensuring the right amount of inventory is in the right place at the right time.

- Demand Forecasting and Planning: Using data analytics and forecasting models to predict future demand.

- Inventory Planning and Control: Setting optimal inventory levels, reorder points, and safety stock.

- Replenishment Management: Automating or managing the process of restocking inventory.

- Slow-Moving and Obsolete Stock (SLOB) Management: Identifying and developing strategies for excess or outdated inventory.

- Inventory Visibility Solutions: Leveraging provider technology for real-time tracking of inventory across the network.

- Keywords: Inventory management outsourcing, Demand planning BPO, Inventory optimization services.

Contract Manufacturing and Production Support (Extending Your Make-Capacity)

Outsourcing part or all of the manufacturing process.

- Full Contract Manufacturing: A third party manufactures the entire product according to the client's specifications.

- Component Manufacturing or Sub-Assembly: Outsourcing the production of specific parts or an assembly stage.

- Tolling Arrangements: Providing raw materials to a third party for processing.

- While often considered distinct, it's a key part of the broader supply chain for many product-based companies.

- Keywords: Contract manufacturing outsourcing, Manufacturing BPO, Outsource production assembly.

Reverse Logistics and Returns Management (Closing the Loop Efficiently)

Managing the process of products moving backward from the customer to the seller or manufacturer.

- Returns Processing: Receiving, inspecting, and processing customer returns.

- Product Disposition: Deciding whether returned items should be restocked, refurbished, recycled, or disposed of.

- Warranty Management and Repairs: Handling warranty claims and product repairs.

- Recalls Management: Executing product recalls efficiently.

- Keywords: Reverse logistics outsourcing, Returns management services, 3PL returns processing.

Supply Chain Planning, Analytics, and Visibility (The Brains of the Operation)

Leveraging data and expertise to make strategic supply chain decisions.

- Sales and Operations Planning (S&OP) Support: Facilitating or providing data for the S&OP process.

- Supply Chain Network Design and Optimization: Analyzing and redesigning the supply chain for efficiency and resilience.

- Supply Chain Analytics and Reporting: Providing insights into performance, costs, and risks.

- Control Tower Solutions: Centralized hubs (often technology-enabled) providing end-to-end visibility and coordination, sometimes managed by a 4PL or specialized provider.

- Predictive Analytics for Risk Management: Identifying potential disruptions and bottlenecks.

- Keywords: Supply chain analytics outsourcing, S&OP BPO, Supply chain visibility solutions, Control tower services.

Supply Chain Customer Service (The Voice to Your Customers)

Handling customer interactions related to orders, shipments, and issues.

- Order Tracking and Status Updates: Providing customers with information about their orders.

- Issue Resolution: Addressing delivery problems, damages, or discrepancies.

- Post-Sales Support Related to Logistics: Answering queries about shipping, returns, etc.

- Keywords: Supply chain customer service outsourcing, Logistics call center, Order management BPO.

Customs Brokerage, Trade Compliance, and International Freight

Navigating the complexities of international trade.

- Customs Clearance: Ensuring compliance with import/export regulations and handling documentation.

- Tariff Classification and Duty Optimization: Minimizing duties and taxes legally.

- Trade Compliance Consulting: Advising on international trade laws and agreements.

- Managing Documentation: Letters of credit, bills of lading, certificates of origin.

- Keywords: Customs brokerage outsourcing, Trade compliance services, International freight management.

Essential Back-Office Supply Chain Support Functions

Administrative tasks that keep the supply chain moving.

- Data Entry and Management: Inputting order details, shipment information, inventory counts.

- Documentation Management: Organizing and maintaining supply chain-related paperwork.

- Reporting and Basic Analytics: Generating standard performance reports.

- Freight Bill Auditing and Payment (FBAP): Verifying and paying freight invoices.

- Keywords: Supply chain BPO services, Logistics data entry outsourcing, Freight audit BPO.

Identifying which of these (or other) roles and operations are ripe for outsourcing requires a careful assessment of a US business's core competencies, strategic goals, cost structure, and risk appetite. This often involves a detailed internal review before engaging with potential outsourcing partners.

For US businesses navigating an increasingly complex and competitive global landscape, strategically outsourcing supply chain roles and operations can unlock a multitude of compelling advantages. These benefits often extend beyond mere cost savings, touching upon efficiency, expertise, scalability, and strategic focus.

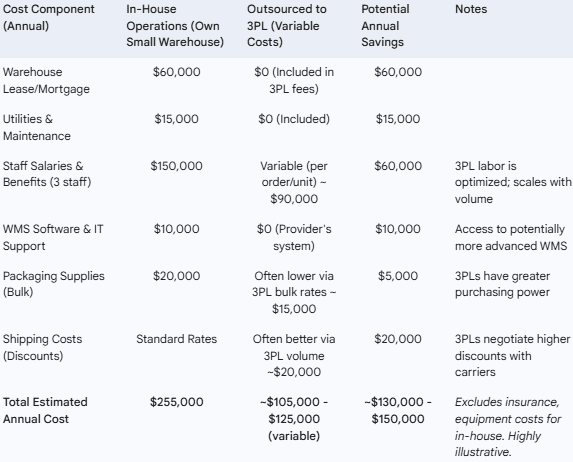

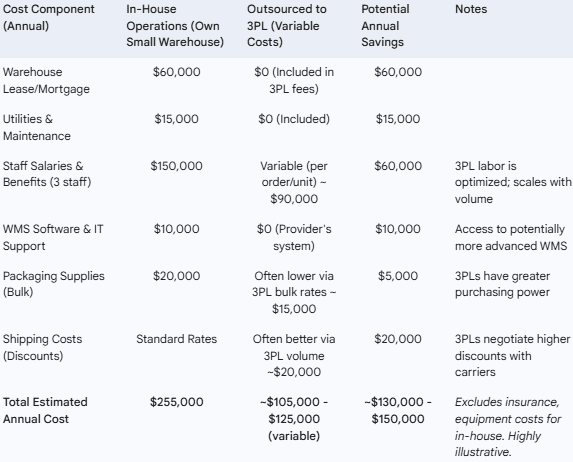

Substantial Cost Reduction and Enhanced Operational Efficiency

This remains a primary driver, offering tangible financial relief and streamlined processes.

- Harnessing Economies of Scale from Specialized Providers: Outsourcing partners, especially large 3PLs or specialized BPOs, serve multiple clients. This allows them to achieve economies of scale in warehousing, transportation, technology, and labor that individual businesses often cannot match. This can translate to lower per-unit costs for services like fulfillment or freight.

- Mitigating Capital Expenditure in Infrastructure and Technology: Building and maintaining warehouses, purchasing fleets of trucks, or investing in sophisticated Warehouse Management Systems (WMS), Transportation Management Systems (TMS), or advanced analytics platforms requires significant upfront capital and ongoing maintenance costs. Outsourcing allows businesses to access these capabilities on a variable cost basis, freeing up capital for core activities like product development or marketing.

- Leveraging Global Labor and Operational Cost Differentials: Outsourcing specific functions (e.g., back-office support, data analytics, customer service for supply chain) to nearshore or offshore locations can significantly reduce labor costs. Even for physical logistics, providers in lower-cost domestic regions or with optimized labor models can offer savings.

Outsourcing partners are specialists in their respective domains.

- 3Tapping into Decades of Accumulated SCM Expertise: Reputable providers bring years, often decades, of experience managing complex supply chains across various industries. They possess deep knowledge of logistics networks, regulatory environments, carrier management, procurement strategies, and inventory optimization techniques that would be difficult and time-consuming for a non-specialist company to develop in-house.

- Gaining Access to Cutting-Edge SCM Software and Automation: Leading SCM outsourcers invest heavily in advanced technologies such as sophisticated TMS, WMS, real-time visibility platforms, robotic process automation (RPA) for back-office tasks, AI-powered demand forecasting, and warehouse automation (e.g., AGVs, automated picking systems). Clients benefit from these technologies without bearing the full cost of acquisition, implementation, and maintenance.

Sharpened Focus on Core Business Competencies and Strategic Growth

Delegating non-core SCM functions allows companies to concentrate their resources and energy where they add the most value.

- Liberating Management to Concentrate on Innovation, Product Development, and Market Expansion: Managing the intricacies of a supply chain can be a significant drain on management time and attention. Outsourcing allows leadership to focus on core strategic initiatives like R&D, brand building, sales growth, and customer relationship management, which are often the true drivers of competitive differentiation.

Unprecedented Scalability, Flexibility, and Market Responsiveness

Outsourcing provides the ability to rapidly adjust supply chain capacity and reach.

- 3Seamlessly Adapting to Demand Volatility and Seasonality: Many businesses experience fluctuations in demand. Outsourcing partners can scale resources (warehouse space, labor, transportation capacity) up or down quickly to match these peaks and troughs, converting fixed operational costs into variable ones. This is particularly crucial for businesses in retail, e-commerce, or industries with seasonal products.

- Accelerating Entry into New Geographic Markets or Product Lines: When expanding into new regions or launching new products, leveraging an outsourcing partner's existing infrastructure and local market knowledge can significantly reduce the time, cost, and risk associated with setting up new supply chain operations from scratch.

Increased Operational Efficiency and Faster Speed-to-Market

Specialized providers often bring optimized processes and networks.

- Benefiting from Optimized Processes and Established Global Networks: SCM providers have refined their processes over many engagements. They often have established relationships with carriers, customs officials, and other stakeholders, which can streamline operations, reduce transit times, and ensure smoother cross-border movements. This efficiency can translate into faster order fulfillment and quicker delivery of products to market.

Enhanced Risk Mitigation, Resilience, and Business Continuity

In an uncertain world, outsourcing can help diversify and mitigate supply chain risks.

- Diversifying Operational Vulnerabilities Across Partners and Geographies: Relying on a single in-house facility or network can expose a business to significant risk from local disruptions (e.g., natural disasters, labor strikes, infrastructure failures). Outsourcing to providers with multiple locations or established contingency plans can help distribute this risk.

- Leveraging Provider Networks for Agile Response to Disruptions: Experienced SCM providers often have broader networks and more flexibility to reroute shipments, find alternative capacity, or shift operations in response to unexpected events like port congestion, geopolitical instability, or supplier issues, contributing to overall supply chain resilience.

Improved Customer Service Levels and Enhanced Satisfaction

An efficient supply chain directly impacts the end customer's experience.

- Achieving Faster Delivery Times, Higher Order Accuracy, and Better Communication: Specialized fulfillment providers, for example, often have systems and processes designed to maximize order accuracy and shipping speed. Many also offer advanced tracking and customer communication tools, leading to increased transparency and satisfaction. This is critical in today's customer-centric environment.

Potential for Improved Supply Chain Visibility and Control (with the right partnerships and technology)

While loss of control is a common fear (see Pitfalls section), partnering with a technologically advanced SCM provider can actually enhance visibility.

- Many providers offer sophisticated client portals and data dashboards that provide real-time insights into inventory levels, shipment statuses, and performance metrics. This data-driven approach can lead to better-informed decision-making and a greater sense of control than might be achievable with less advanced in-house systems.

By strategically leveraging these advantages, US businesses can transform their supply chains from a cost center into a powerful enabler of growth, customer satisfaction, and competitive strength. The key lies in careful planning, diligent partner selection (where platforms like Bpohub can be invaluable), and robust ongoing management of the outsourcing relationship.

For US business owners, the decision to outsource supply chain roles and operations is a significant strategic undertaking, fraught with both immense opportunity and considerable risk. The "labyrinth" of global supply chains requires careful navigation, but those who master it can unlock substantial competitive advantages.

- Critical Takeaways for US Business Owners: Success hinges on a clear strategy, rigorous partner selection, robust governance, a commitment to collaboration, and a proactive approach to risk management. Outsourcing is not a "set it and forget it" solution.

- Mastering the Balance: Leveraging Advantages While Proactively Mitigating Pitfalls: The goal is to harness the cost savings, expertise, scalability, and technological advancements offered by specialized providers while diligently safeguarding against loss of control, quality issues, data breaches, and reputational damage.

- Your Next Move: Discover Tailored Supply Chain Outsourcing Solutions with Bpohub: Embarking on or optimizing your supply chain outsourcing journey requires expert guidance. Bpohub is dedicated to connecting US businesses with a global network of vetted, high-quality supply chain service providers. We help you cut through the complexity, mitigate risks, and find partners who can transform your supply chain into a powerful engine for growth and resilience.